Breeder flat raising equipment Cota

Classification:

Key words:

- Product Description

-

Material Tower Parameter Price List

Model

Theoretical capacity

tons

Volume

m³

self-weight

kg

Height

Upper cone plate

Thickness mm/Quantity

Enclosing

Thickness mm/Quantity

Lower cone plate

Thickness mm/Quantity

Leg

Thickness mm/Quantity

Upper and lower cones

Angle

Layer 1834-1

3.0

4.6

330

4.1

1.0

6

1.0

2

1.2

6

2.5

4

30°/67°

Floor 1834-2

4.5

6.9

400

5.0

1.0

6

1.2

1.0

1.2

6

2.5

4

30°/67°

1834-Level 3

6.0

9.2

460

5.9

1.0

6

1.2

1.0

1.0

1.2

6

2.5

4

30°/67°

Model

Theoretical capacity

tons

Volume

m³

self-weight

kg

Height

m

Upper cone plate

Thickness mm/Quantity

Enclosing

Thickness mm/Quantity

Lower cone plate

Thickness mm/Quantity

Leg

Thickness mm/Quantity

Upper and lower cones

Angle

Layer 2750-1

7.5

11.6

595

4.7

1.0

9

1.0

3

1.2

9

2.5

6

30°/60° 2750-2 layer

11.0

16.8

690

5.6

1.0

9

1.2

1.0

3

1.2

9

2.5

6

30°/60°

2750-3 floor

14.3

22.0

770

6.5

1.0

9

1.2

1.0

1.0

3

1.2

9

2.5

6

30°/60°

2750-4 floor

17.7

27.2

880

7.4

1.0

9

1.2

1.0

1.0

1.0

3

1.2

9

3

6

30°/60°

Model

Theoretical capacity

tons

Volume

m³

self-weight

kg

Height

m

Upper cone plate

Thickness mm/Quantity

Enclosing

Thickness mm/Quantity

Lower cone plate

Thickness mm/Quantity

Leg

Thickness mm/Quantity

Upper and lower cones

Angle

Layer 3668-1

15.8

24.3

940

5.7

1.0

12

1.0

4

1.5

12

3

8

30°/60° Layer 3668-2

21.8

33.6

1070

6.6

1.0

12

1.2

1.0

4

1.5

12

3

8

30°/60° Layer 3668-3

27.9

42.9

1180

7.5

1.0

12

1.2

1.0

1.0

4

1.5

12

3

8

30°/60°

Level 3668-4

33.9

52.2

1295

8.4

1.0

12

1.2

1.0

1.0

1.0

4

1.5

12

3

8

30°/60°

Flexible way of use

01 Tile method, 02 Leg support type, 03 Suspension installation method

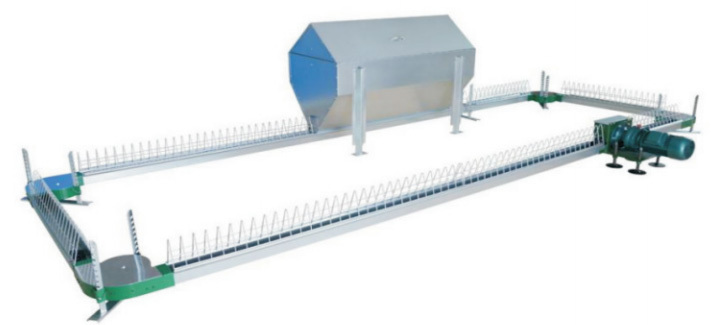

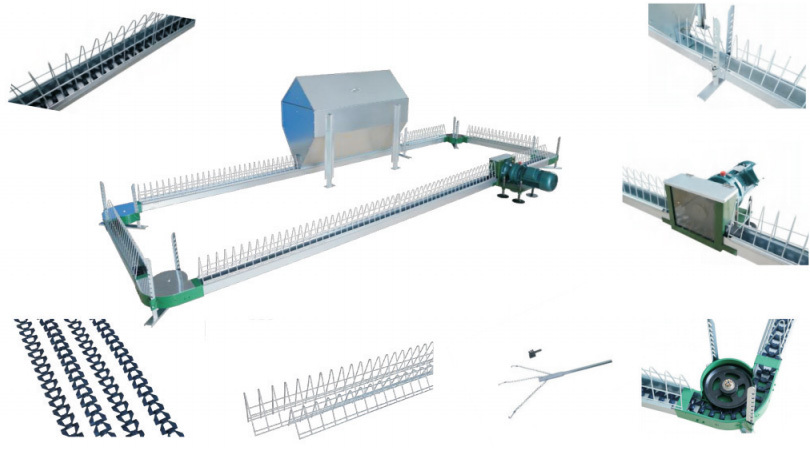

Hen chain feeding system

Configuration Standard:

① The trough is 275g hot galvanized sheet for numerical control bending, the thickness of the sheet is not less than 1.2mm,3 meters per root, each meter can be fed by 12 hens.

② Equipped with hot-dip galvanized wire, the feeding grid is limited to 1.5 meters each, the wire diameter is not less than 4.0mm, the feeding mouth size is 46mm * 65mm, and the bidirectional reinforcing rib design.

③ The joint of the trough is made of 275g hot-dip galvanized sheet with a thickness of not less than 2.0mm.

④ Each loop of the material line is equipped with a well-known brand driver and a shim protection plate, which is closely matched with the gear. Contains a habitat shield.

⑤ Each ring of material line is equipped with 2 large material boxes with a volume of not less than 280KG, and the whole material is 275g hot-dip galvanized sheet. The thickness of the box body is not less than 1.2mm, the thickness of the leg is not less than 2.0mm, and the height of the leg can be adjusted.

⑥ Each circulating material line is equipped with 4 turning angle devices. The inner wheel is high-frequency quenched and designed as double bearings with strong tensile wear resistance.

⑦ The distribution box uses famous brand electrical components, which can independently control the operation of each loop of material line.

Patented Double Bearing Corner

★The corner wheel is made of special high-strength alloy steel with high hardness, high wear resistance and high life.

★The axle is a high-strength maintenance-free human-centered double bearing, which is simple and convenient.

★The outer layer of the corner shell is treated with anti-static plastic spraying.

★The corner is equipped with limited feeding grid end cap.

★The runner is made of 45# cast steel, which has HRC50-52 quenching hardness and excellent wear resistance.

★The shaft design is compact and limited to avoid feed entering the bearing.

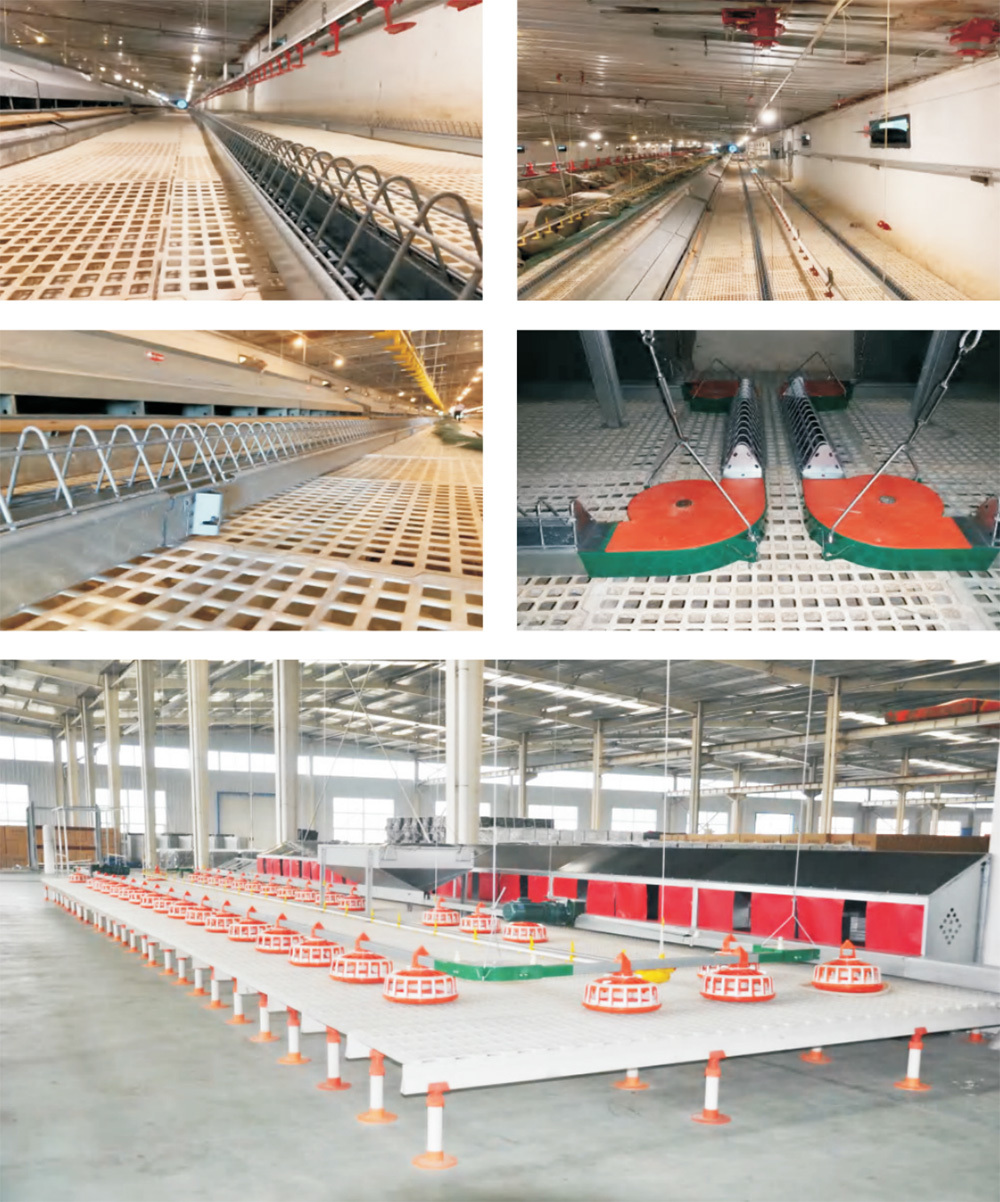

Hen chain material line project case

Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!